9 Easy Facts About Aws Cwi Shown

9 Easy Facts About Aws Cwi Shown

Blog Article

Unknown Facts About Aws Cwi

Table of ContentsThe Basic Principles Of Aws Cwi The Definitive Guide for Aws CwiSome Ideas on Aws Cwi You Need To KnowThe Aws Cwi DiariesThe 10-Second Trick For Aws Cwi

Have you ever took into consideration a career as a welding inspector? A welding inspection certification is not just an excellent achievement, it verifies your capabilities in the welding industry.

Becoming a Certified Welding Assessor shows your commitment to growing within the welding sector. This accreditation is one that need to not and will not be ignored! As a CWI, you'll be able to make the most of a variety of different chances amongst sector experts.

As you might understand, welding is one of the most intricate services within the metal manufacture industry (https://www.pinterest.com/pin/982136631350953777). The outcome of every welding job is extremely reliant upon private welder ability.

Fascination About Aws Cwi

There's no question that CWIs help to maintain better degrees of consistency and high quality to the welding divisions they supervise. This post gives a quick review of the major advantages of dealing with a steel construction firm that employs licensed weld assessors. It's not unexpected that a lot of prominent sectors will require you to hire licensed welding examiners to oversee welding.

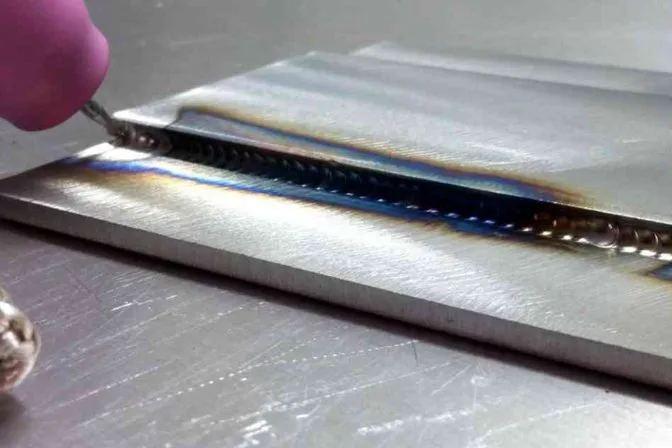

Qualified welding inspectors have years of experience and thus, they comprehend the subtleties of conformity with welding codes. Following the welding process, CWIs can conduct a series of examination to check the top quality of a weld, consisting of aesthetic examination, warmth treatment and a hydrostatic test. CWI Welding Inspector. They can likewise make the appropriate modifications to the pre-weld prep work and the in-weld treatments as necessary

An internal certified welding inspector will be able to assure that your task is tailored to all the requirements of relevant welding codes, ensuring its top quality. Welding examiners can evaluate welding treatment requirements, building and welding plans, devices calibration and welding products. A welding examiners capacity to supply welding treatment specifications offers the steel fabrication firm a considerable edge of the competitors, allowing producers to develop welds that ideal fit specific components, rather than utilizing tried-and-true welds.

Aws Cwi - Questions

As previously pointed out, a CWI is not just accountable fore composing the treatments for the weld, however likewise the quality-check testing treatments. http://peterjackson.mee.nu/where_i_work#c2362. Past that, welding assessors work to make sure that equipment is correctly prepped for the work which welders are able to complete their welds with competence (Weld Inspection). A certified welding inspector will certainly have had years of experience, which a steel construction business can take advantage of to make certain stellar results for all construction jobs that entail welding

This is why it's critical to locate a welding firm with a skilled and very educated internal certified welding inspector on staff. Thankfully, CAMM steels is such a business, so call us today if you have an upcoming project that requires quality customized welding! It's clear that a custom steel construction supplier with internal CWIs has devoted to purchasing the high quality of its welds.

Additionally, some sectors require CWIs to be included in the production of components. In the long run, CWIs presume a fair bit of duty, yet their experience displays in the end product. Below at CAMM Metals, after the welding section of the task is complete, we supply many internal solutions. These solutions consist of weld examination with color penetrant, acid cleansing and polishing of stainless steel welds.

For those customers who require licensed welds, we can license our welds to AWS D1.1 & AWS D1.6.

The Facts About Aws Cwi Uncovered

It's essential to keep in mind that many employers do not constantly need welders to be licensed. The main distinction is that certified welders have actually written documents of their examination results and their performance is regularly kept an eye on with regular evaluation( s) being component of the efficiency document for each welder.

Prior to taking the examination all PFS welders are trained, if required, in the actual welding process that they will certainly be using and they will need to have a functioning expertise of the welding devices, welding consumable and the product to be bonded. Efficiently passing one examination will certainly permit the welder to service lots of sorts of manufactures yet will certainly not allow him to service great post to read all types of construction as there are credentials ranges imposed for each examination arrangement.

Vital variables include but are not restricted to product type, consumable kind, material density and welding placement. and so on. After the welder has actually finished his test plate or pipeline the weld is evaluated using the following NDE procedures: Aesthetic Evaluation X-Ray Fluid Penetrant Screening In some situations, the weld is also destructively tested.

The Aws Cwi Ideas

PFS achieves this using a continuity record that information all welds that a welder makes. If a welder does not use the welding process in a 6-month duration, after that they will be requalified in that process. The advantages to utilizing a qualification system are several however the significant advantages are: It validates the ability of an individual to carry out in accordance with a qualified welding procedure specification (WPS) to create an excellent weld.

Report this page